Related Products

Product Information

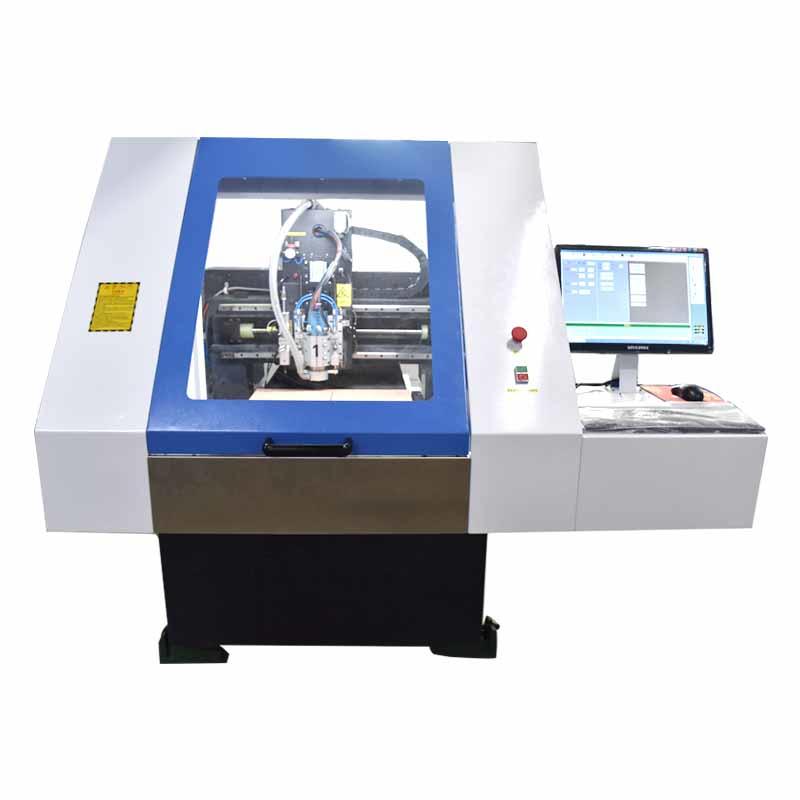

| SINGLE HEAD PCB DRILLING AND ROUTING MACHINE | |||

| NO. | ITEM | CK-01R | |

| 1 | spindle number | 1 | |

| 2 | tool change | Automatic | |

| 3 | spindle model | JV-80 | |

| 4 | spindle speed | 80000rpm | |

| 5 | spindle power | 1.2KW | |

| 6 | spindle cooling | Water-cooling | |

| 7 | X.Y.Z rail | Germany | |

| 8 | X.Y. Z ballscrew | Germany | |

| 9 | X.Y rapid speed | 30m/min | |

| 10 | Z rapid speed | 30m/min | |

| 11 | routing accuracy | ±0.05mm | |

| 12 | positioning accuracy | ±0.005mm | |

| 13 | repeatability accuracy | ±0.005mm | |

| 14 | machine material | Granite | |

| 15 | drive system | Delta / Panasonic | |

| 16 | NC system | CHIKIN | Sieb & Meyer cnc 82 |

| 17 | operating interface | English | |

| 18 | table dimension | 560 * 680mm | |

| 19 | tool magazine capacity | 10 PCS | |

| 21 | drilling tool diameter | 0.5-6.35mm FR4 | |

| 22 | routing tool diameter | 0.6-3.175mm | |

| 23 | spindle over-heat protection | Included | |

| 24 | tool length detection | Included | |

| 25 | air supply | 0.6~0.8 MPa | |

| 26 | power supply | 220V 1ph, 50HZ | |

| 27 | machine dimension | 1720*1880*1600mm | |

| 28 | weight of the machine | 1500KG | |

| SINGLE HEAD PCB DRILLING AND ROUTING MACHINE | |||

| NO. | ITEM | CK-01R | |

| 1 | spindle number | 1 | |

| 2 | tool change | Automatic | |

| 3 | spindle model | KLKJ-60C | |

| 4 | spindle speed | 60000rpm | |

| 5 | spindle power | 1.2KW | |

| 6 | spindle cooling | Water-cooling | |

| 7 | X.Y.Z rail | Taiwan | |

| 8 | X.Y. Z ballscrew | Taiwan | |

| 9 | X.Y rapid speed | 20m/min | |

| 10 | Z rapid speed | 20m/min | |

| 11 | routing accuracy | ±0.05mm | |

| 12 | positioning accuracy | ±0.01mm | |

| 14 | machine material | Granite | |

| 15 | drive system | Delta Servo Motor | |

| 16 | NC system | CHIKIN | |

| 17 | operating interface | English | |

| 18 | table dimension | 560 * 680mm | |

| 19 | tool magazine capacity | 10 PCS | |

| 21 | drilling tool diameter | 0.5-6.35mm | |

| 22 | routing tool diameter | 0.6-3.175mm | |

| 23 | spindle over-heat protection | Included | |

| 24 | tool length detection | Included | |

| 25 | air supply | 0.6~0.8 MPa | |

| 26 | power supply | 220V 1ph, 50HZ | |

| 27 | machine dimension | 1720*1880*1600mm | |

| 28 | weight of the machine | 1500KG | |

Logistics

We support both OEM & ODM packaging. Our normally delivery method are by the sea, by air, by international express (DHL, UPS, TNT, FedEx)

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved