Related Products

Product Information

| Depth Control PCB DRILLING AND ROUTING MACHINE | ||||

| Model | CK-04R / 02R | |||

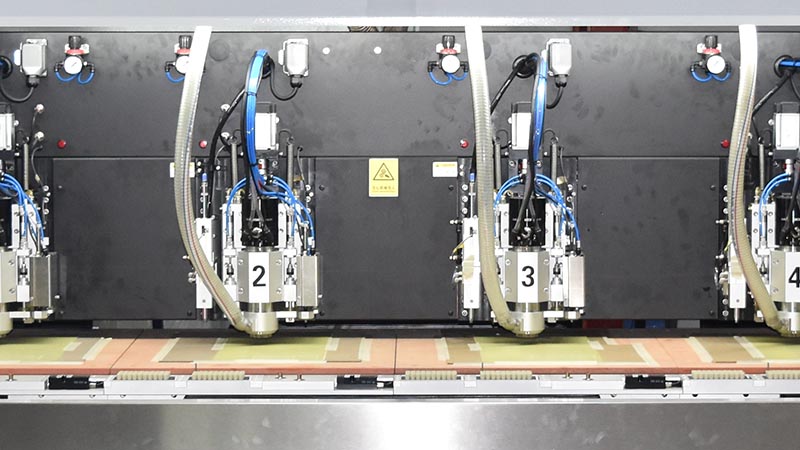

| tool change | Automatic | |||

| spindle speed | 60000rpm | |||

| spindle power | 1.2KW | |||

| X.Y.Z rail | Germany | |||

| X.Y.Z ballscrew | Germany | |||

| X.Y rapid speed | 30m/min | |||

| Z rapid speed | 30m/min | |||

| linear scale | resolution 0.001mm | |||

| Depth control accuracy | ±0.03mm(By ChiKin condition) | |||

| routing accuracy | ±0.05mm(By ChiKin condition) | |||

| positioning accuracy | ±0.005mm | |||

| drive system | Delta Motor | Panasonic Servo Motor | ||

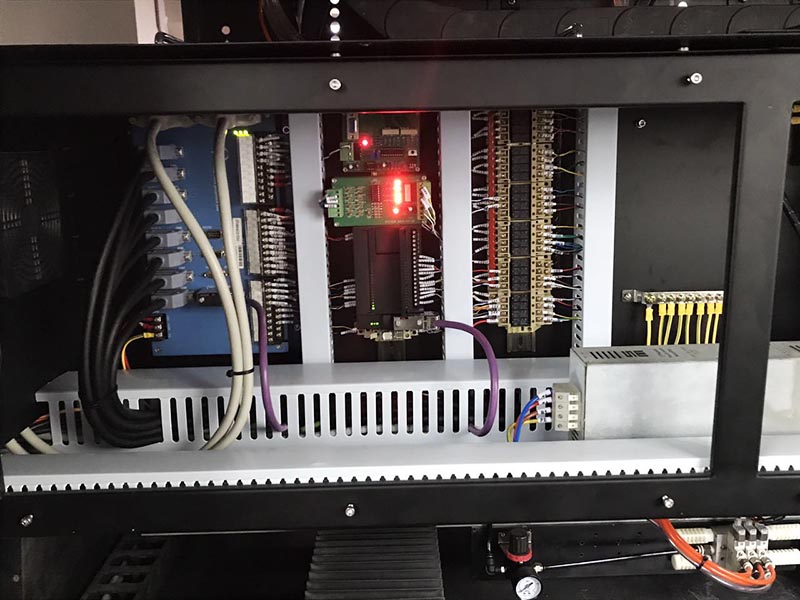

| NC system | CHIKIN CNC | |||

| operating interface | English | |||

| table dimension | 560*680mm | |||

| drilling tool diameter | Aluminium:0.8~6.0mm; FR4:0.5~6.35mm | |||

| routing tool diameter | Aluminium:0.8~3.175mm; FR4:0.5~3.175mm | |||

| tool length detection | Included | |||

| Stripping Way | Automatic | |||

| available processing material | FR1, FR4, CEM-1/2/3, Aluminium | |||

Product Description

▣ Support spindle over-heat protection

▣ Automatic tool change

▣ Tool length management

▣ Available to sigle sided, double sided and multi-layer aluminum pcb/fr4 pcb/acrylic pcb/copper pcb etc

▣ Support customizing

Logistics

We support both OEM & ODM packaging. Our normally delivery method are by the sea, by air, by international express (DHL, UPS, TNT, FedEx)

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved